Optimization and Integration for Subsea Umbilicals Risers and Flowlines

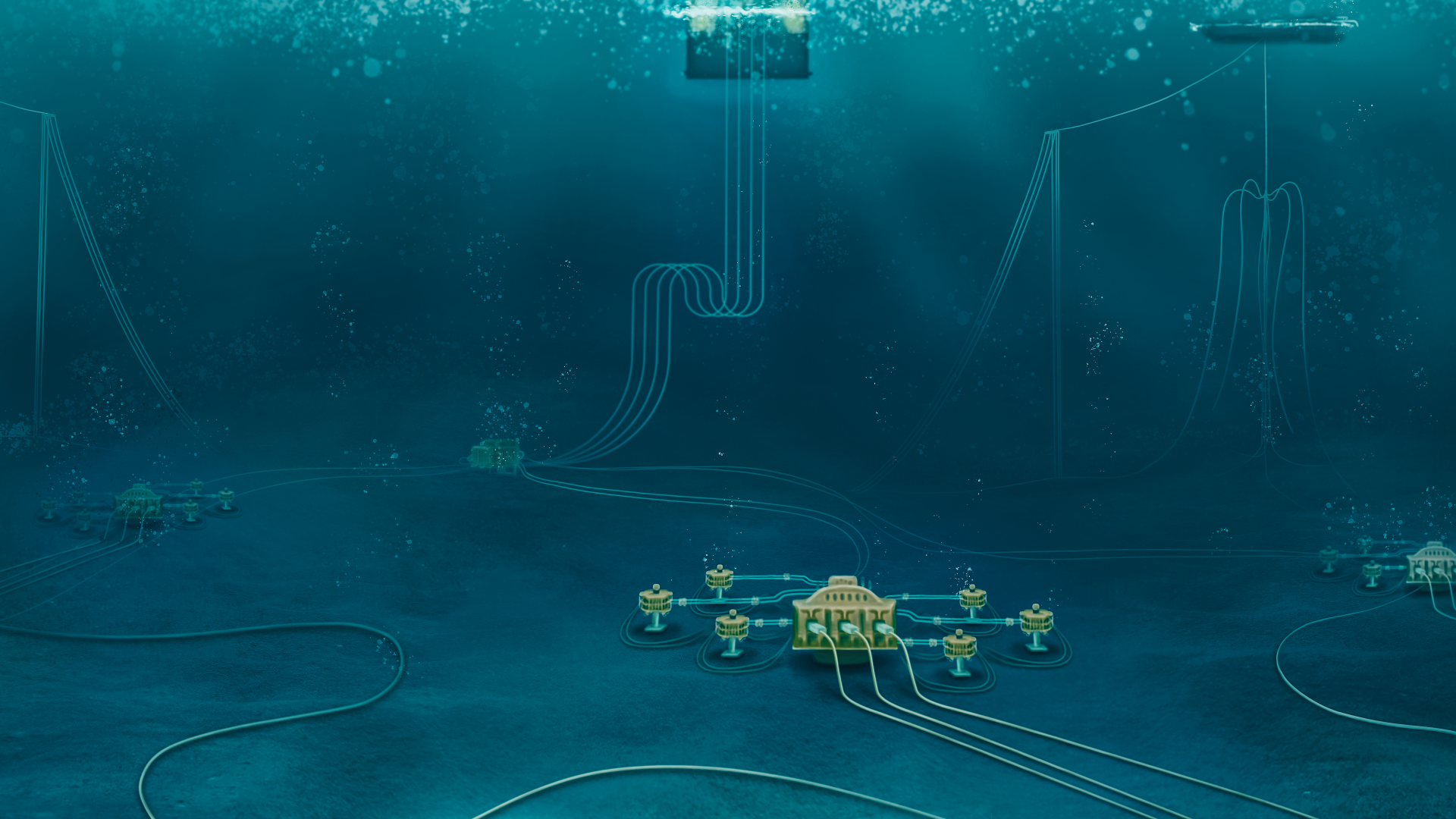

Subsea Umbilicals Risers and Flowlines (SURF) connect subsea production facilities to surface systems, playing a crucial role in the extraction and transportation of hydrocarbons from the seabed to platforms and the coast.

NSG is specialist in Subsea Umbilicals Risers and Flowlines (SURF) projects, including all necessary analyses for in-place condition and installation, whether involving rigid or flexible structures.

Service Portfolio for Subsea Umbilicals Risers and Flowlines

Riser extreme analyses;

Wave induced, heave induced and VIV fatigue analyses;

Interference analysis of Riser-Riser and Riser-Mooring;

Installation analysis of flexible lines;

Free span assessment;

Lateral and upheaval buckling analyses;

Ultimate and Fatigue Limit State analyses of pipelines;

Pipeline crossing design;

Integrity and Life extension assessment of rigid pipelines;

Pipeline In-Situ Verifications;

Torpedo and suction pile design and installation analysis;

Challenge

Ensuring the integrity of rigid pipelines considering VIV (Vortex-Induced Vibration) in free spans and corrosion on the pipe walls over their service life.

Solution

We apply internationally accepted standards endorsed by regulatory bodies such as ANP and IBAMA, as well as operators like Petrobras (PIDR), to assess the integrity of corroded pipelines, taking VIV and data from instrumented pigs into account over their service life or for extended service. This enables us to safely predict operational conditions that allow for secure operation under the specific conditions of each pipeline.

Challenge

Conducting interference analyses between risers that adhere to Petrobras Technical Specification (ET) standards.

Solution

We have extensive experience with the methodology required by Petrobras for riser interference analyses. Furthermore, through automation techniques and the use of the right analytical tools, we can offer efficient solutions for your project.

Challenge

Safely handling flexible pipes and umbilicals while considering the limitations of available construction vessels.

Solution

We develop detailed operational procedures and conduct analyses using simulations to determine the best conditions for safely and efficiently conducting subsea installations. Additionally, we dimension and verify the components as well as the structure of the flexible pipe or umbilical to meet the operation's requirements.

Operational Reliability: Standpipe Failure in Drilling Operations

Ensuring operational reliability is paramount in the dynamic landscape of drilling operations. This white paper delves into a detailed Root Cause Analysis (RCA) conducted to investigate a standpipe failure during drilling operations. This study aimed to provide...

Exploring Offshore Wind: Meet NSG’s BRAVO 2.0

Find out how NSG is collaborating with meteorological measurement for offshore wind together with Petrobras and ISI-ER!Since 2022, NSG's team of engineers has been working on the project of a Remote Offshore Wind Measurement Buoy, the BRAVO 2.0. This equipment,...

Explorando Eólica Offshore: Conheça a BRAVO 2.0 da NSG

Descubra como a NSG está revolucionando a o desenvolvimento de eólica offshore com o ISI-ER e a Petrobras!Desde 2022, o time de engenheiros da NSG trabalha no projeto de uma Boia Remota de Avaliação de Ventos Offshore, a BRAVO 2.0. Este equipamento, desenvolvido pelo...